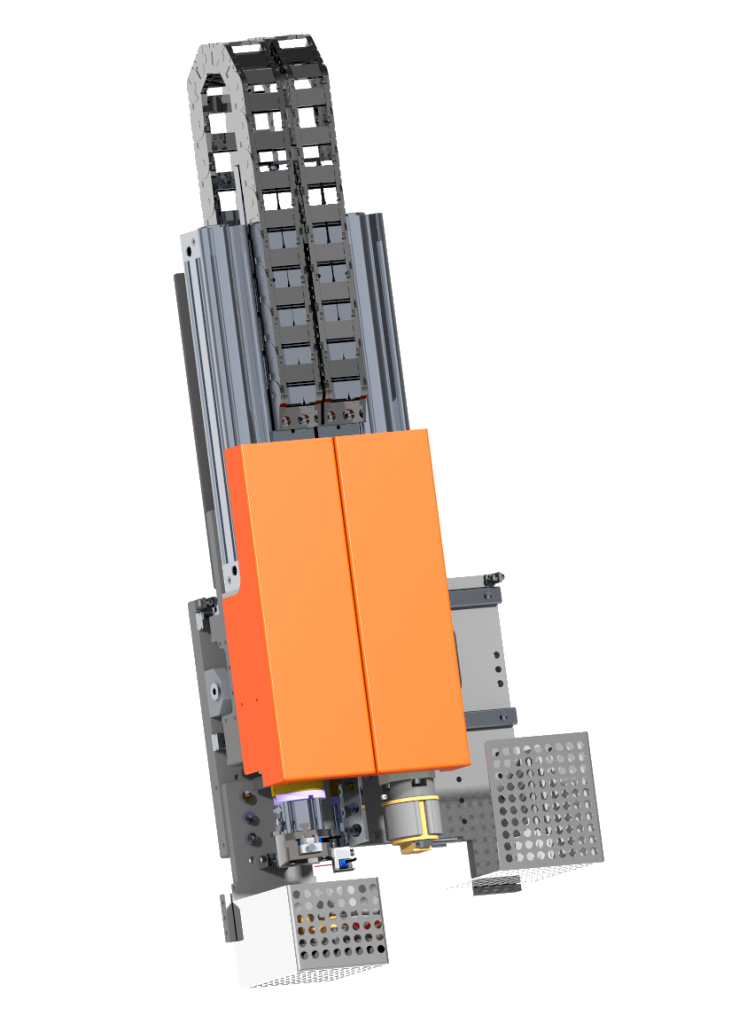

Hot plate /

welding unit

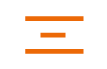

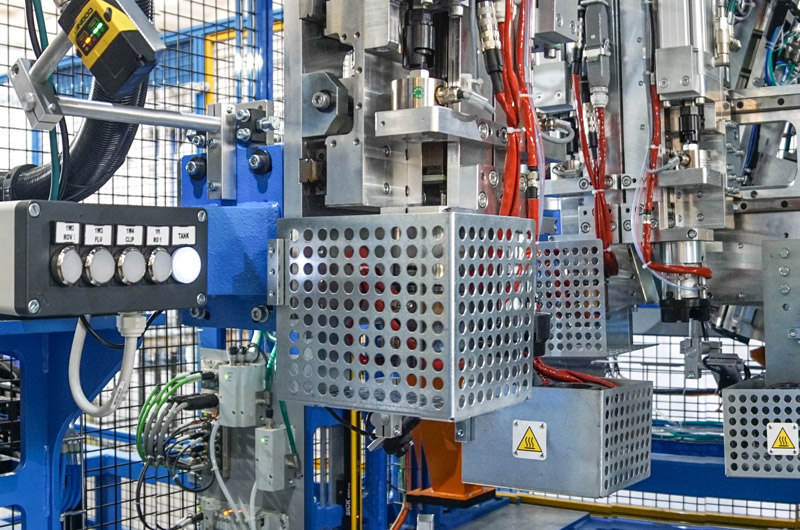

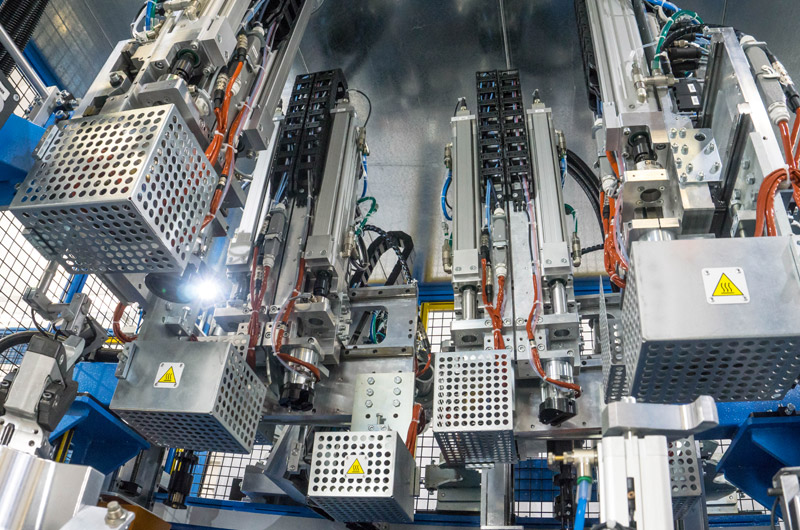

Euromodel Engineering developed this totally indipendent hot plate welding unit. It’s composed by electric valves, the proportional valves and the electrical connection, these are all easily and fastly using a connector. The unit is made of two pneumatic cylinders with antirotation and stiffening guide. Each unit is mounted on an adjustable stand. The weld is obatained dosing force, position, temperature and time. All parameters are available on the operator panel. The hot plate welding machine is designed to weld some plastic accessories onto a master plastic parts, such as valves, fuel tank, fuel inlet tube, all by hot plastic welding procedure. The Euromodel machines are designed basing on a customer requirement and parts data.