Products /

Machinery

Welding and mounting of thermoplastic components are carried out with various systems depending on requirements. Our products can be standard or made-to-order.

It goes by definition that thermoplastic material are sensitive to heat it

Our Welding techniques are:

Ultrasonic Welding

fastest and most versatile of all welding processes.

Due to the partnership with SONIC,

we combine technique and innovation.

Hot Plate Welding

parts of the EUROMODEL standard machinery.

Thanks to decades of R&D, today we have a

remarkable know-how related to this technology.

Laser

and CO2 laser welding technology in its catalog:

the most innovative and flexible machinery that

we provide at your disposal.

Fuel Tanks / Finishing

the largest and most complex machinery that

EUROMODEL is able to create.

All our experience at your disposal.

Our Welding techniques are:

Ultrasonic

Ultrasonic Welding is the fastest and most versatile of all welding processes. Due to the partnership with SONIC, we combine technique and innovation.

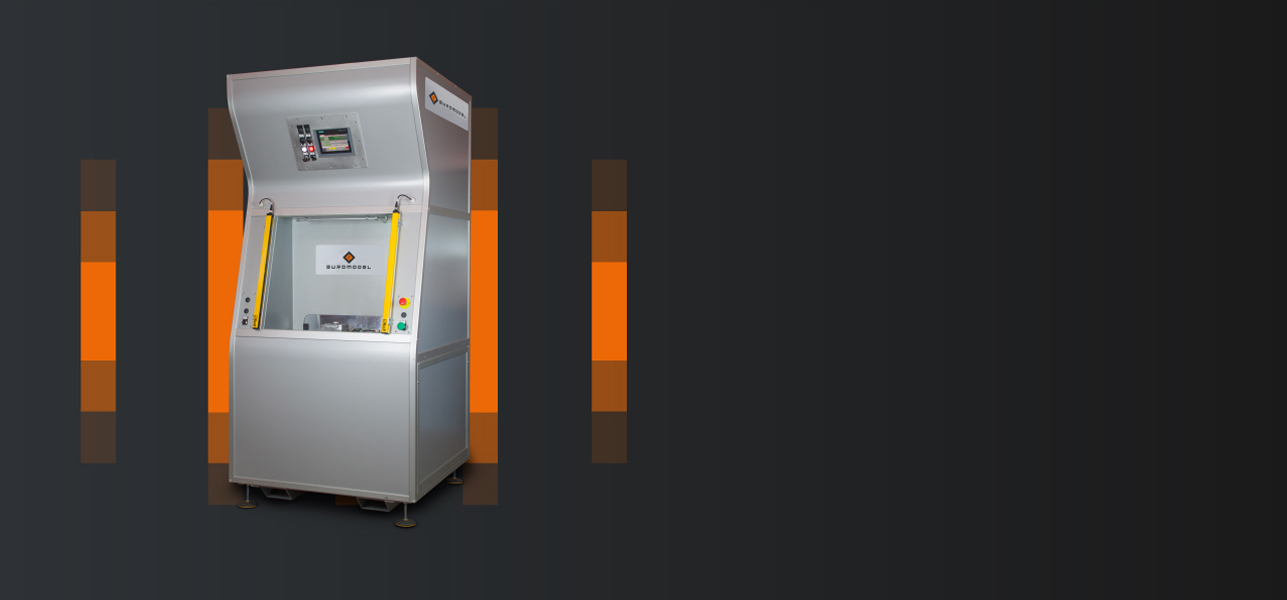

Hot Plate

Hot Plate Welding Machines are parts of the EUROMODEL standard machinery. Thanks to decades of R&D, today we have a remarkable know-how related to this technology.

Laser

Since 2019 EUROMODEL has introduced diode and CO2 laser welding technology in its catalog: the most innovative and flexible machinery that we provide at your disposal.

Fuel Tanks /Finishing

The processing lines of the fuel tanks are among the largest and most complex machinery that EUROMODEL is able to create. All our experience at your disposal.

We love /

Challanges

For those applications that do not fit our standard welding solution, we shall work with you for a tailor-made option to achieve your desired results. With our experience and expertise, we can produce welding appliance and more for any thermoplastic material on the market.